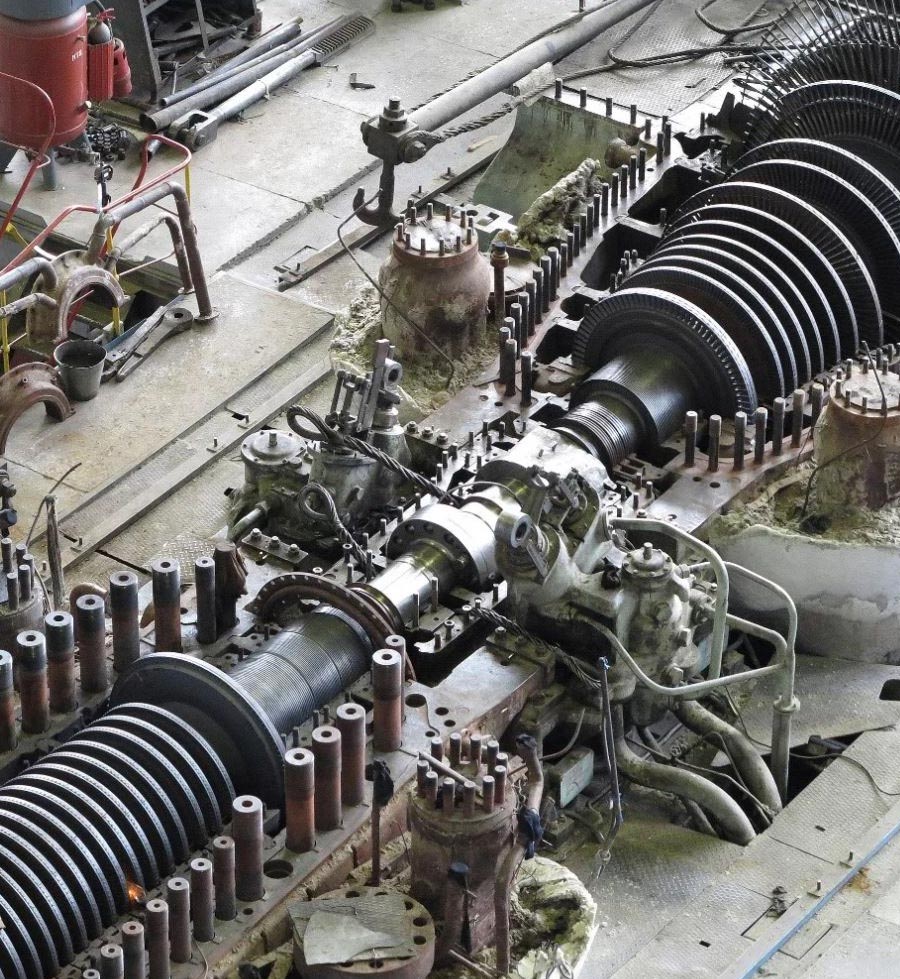

Special Assessments

Looking beyond ‘routine’ steam turbine engineering work, specialised design assessments are sometimes needed and Turbine Mechanics Limited can support you.

HIGH TEMPERATURE FASTENER DESIGN

One of our particular specialities is high temperature fastener design. Thermal power plants use large high-temperature studs and bolts in the turbine cylinders, steam chests and on other equipment. These are potentially dangerous parts, often misunderstood and mistreated. They are retightened periodically and accumulate creep damage to a point where the fastener needs replacing – or risks failure during operation or maintenance. TML can perform lifetime assessments and recommend if fasteners are fit for service or have expired.

To find out more information please get in touch

Other specialist assessments

- Evaluation of axial and radial clearances throughout the steam turbine - the effect on operation and efficiency and the potential to unlock ‘pinch-points’ to improve operational flexibility.

- Wet steam erosion-corrosion assessments, design mitigation and repair recommendations.

- Advice on pipe specification and welding according to ASME B31.1 Power Piping code.

- Assessment of pipework forces and moments on turbine casings and valve chests.

To find out how we can help you